- Facilitate Customer Assembly

- Include a "Tunable" Media Reclaim System

- Simplify Safety & Environmental Compliance

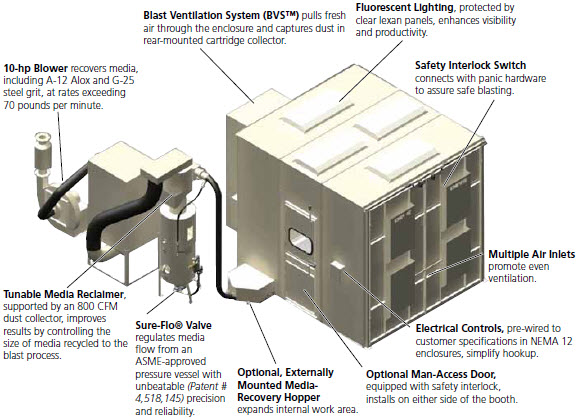

Empire's Pre-Engineered Blast Booths (PEB) feature the essentials of blast rooms at a fraction of the cost. These ten-foot-High booths not only include the hardware required to strip large parts fast. They also reclaim media, remove dust and breathe fresh air into the work enclosure with Empire's exclusive Booth Ventilation System (BVS).

Available in five sizes, these booths ship flat and can be assembled by three people using a forklift or scissor lift in two days. Because the PEB bolts together and requires no excavation, it can be disassembled and set up at a new site in less than a week.

For many applications requiring strict environmental and safety compliance, Empire's Pre-Engineered Booths offer an attractive alternative to makeshift enclosures or Higher priced blast rooms.

All PEB parts-ranging from the central blast and recovery system to pre-wired electrical connections and 14 gauge wall panels-come from Empire, where they have been engineered and built to work in harmony. This assures balanced performance between components and provides users with a single source of responsibility for overall system performance.

Specifications

Standard Blast Enclosures |

N/A

|

Pressure Vessel |

N/A

|

Blast Equipment |

N/A

|

Media Reclaimer |

N/A

|

Pressure Blower for Media Recovery |

N/A

|

Dust Collector for Media Recovery |

N/A

|

Media Conveying Duct |

N/A

|

Media Recovery Hopper |

N/A

|

Media Storage Hopper |

N/A

|

BVS™ for Booth Ventilation |

N/A

|

System Options

|

N/A

|

Operator Safety Equipment (Optional)

|

N/A

|

Warranty

|

N/A

Empire Air-Blast Products |

Environmentally Safe

|

N/A

Air-blasting eliminates many of the environmental problems and costs associated with chemical stripping because you don't have to manage or dispose of hazardous liquids. |