RBT36-F Robotic Blasting Cell

• Advanced Automation

• High-Efficiency Blast and Reclaim

• Intelligent Blasting, Smartly Priced

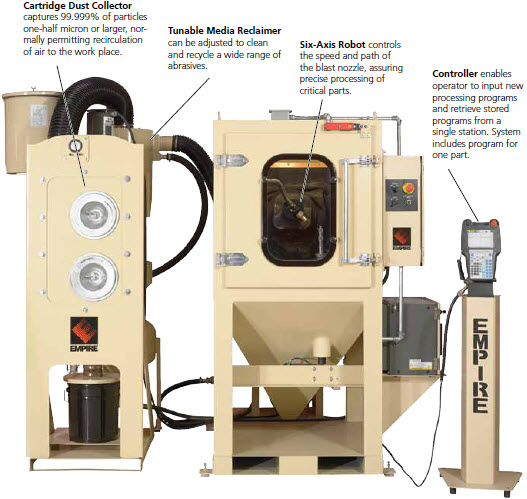

Empire’s new RBT36-F robotic pressure-blast system opens the door for many firms to cash in on the benefits of high precision air blasting. Capable of processing parts up to 12 inches in diameter by 12 inches tall, the RBT36-F employs a Fanuc 6-axis robot to control nozzle movement plus a DC or Servo drive to control part movement, enabling users to assure the quality control and deliver the process validation so often required by today’s aerospace, automotive and medical-equipment sectors.

In addition to helping customers control quality, the RBT36-F reduces the consumption of blast media, energy, floor space and raw materials while boosting the speed, flexibility and yield of manufacturing processes. In short, the system does more with less, contributing to a better bottom line.

The RBT36-F includes dust collection, media reclamation, controls - all the hardware and software required for robotic blasting at standard automation pricing.

In addition to the RBT36-F, Empire produces a larger version of this standard system for parts up to 24” x 24”, as well as engineered robotic systems tailored to specific applications.

Specifications

Standard Components |

N/A

|

Factory Upgrades |

N/A

|

Popular Options |

N/A

Automatic media replenishing system promotes improved results by maintaining the consistency of the abrasive mix. Pneumatically powered, vertically sliding door with infrared light curtain speeds production, conserves floor space and adds safety. Automatic dust cartridge cleaning (photohelic reverse pulse) contributes to smooth performance and frees operator for other tasks. 14” perforated turntable adapts to inherent part station, often reducing costs for 7th axis fixtures. FaStrip® package improves system performance with light media such as plastics. Boron restrictor, recommended in harsh-media applications, extends exhaust valve and reclaimer life. Rubber curtains protect interior of blast enclosure. Sound attenuator (85 dBA) on dust collector reduces noise. Non-slip rubber floor matting improves safety. |