- Batch Finish Parts up to 24" Long

- Process 800 Pounds per Cycle

- Deliver Consistent, On-Spec Results

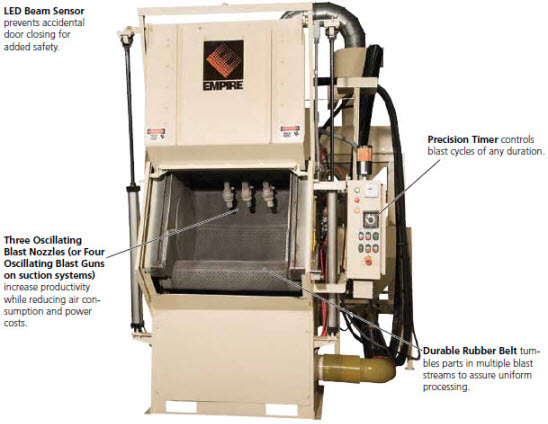

Our CB-3.5 machines, available with either pressure or suction blast systems, automate cleaning, peening, deburring, profiling, finishing and many other surface conditioning tasks. Plus, they handle a vast range of parts formed from casting and injection molding, as well as the molds used to produce the parts. Often, no other finishing method can compare to these heavy-duty production machines in terms of speed and quality results.

Operation is simple: Load parts onto a rugged perforated belt, set the precision timer, and the CB-3.5 does the rest. By tumbling parts within multiple abrasive blast streams, these machines deliver consistent results automatically.

Two models are available: a CB-3.5-S suction system and our more aggressive CB-3.5-P pressure unit, normally preferred in shot peening and other high intensity applications. Both machines have a part-load capacity of 800 pounds.

Empire’s Continuous-Belt Air Blasters process parts of varying shapes, sizes and weights automatically.

Empire’s Continuous-Belt Blasters unload parts with the push of a button. Once processing is complete, the operator opens the door, pushes the "reverse" button and the barrel rotates in the opposite direction to feed work pieces into a post-processing bin.

Specifications

Dimensions (D x W x H) Total CB System Volume |

N/A 195 x 170 x 140 in |

Dimensions (D x W x H) CB Air-Blast Enclosure, Exterior |

N/A 59 x 42-1/2 x 104 in |

Dimensions (D x W x H) Reclaim System, Exterior |

N/A 62 x 62 x 108 in |

Dimensions (D x W x H) Dust Collector, Exterior |

N/A 35 x 40 x 116 in |

CB Part Loading Door (W x H) |

N/A 29 x 24 in |

Barrel Heads Construction |

N/A 4 gauge steel |

Belt Construction |

N/A 1/2" reinforced rubber |

Blast Enclosure Construction |

N/A 4 & 6 gauge steel |

Dust Collector Construction |

N/A 14 gauge |

Reclaimer Construction |

N/A 11 gauge |

Abrasive Charge Capacities |

N/A 700 to 800 lbs |

Dust Collector, Air flow at 11" S. P. Capacities |

N/A 1200 cfm |

Dust Collector, Filtration Area Capacities |

N/A 452 ft² |

Dust Collector, Discharge Drum Capacities |

N/A 16 gal |

Reclaimer Capacities |

N/A 1200 cfm |

Work Mill Capacity |

N/A 800 lbs3-1/2 ft³ |

Blast Nozzles/Guns Quantity |

N/A 3 pressure nozzles |

Blast Nozzles/Guns Size |

N/A 5/16" short venturi |

Blast Nozzles/Guns Material |

N/A Boron |

Blast Nozzles/Guns Pipe string |

N/A 1 in |

Electricals Primary Supply |

N/A 460V/60Hz/3-phase |

Options |

N/A Automatic Media Make-Up System provides fine control of the abrasive or shot mix in applications requiring precise, repeatable surface conditioning. |

Standard Features

|

N/A

|

Warranty

|

N/A

BEST WARRANTY IN THE INDUSTRY |