Blast room equipment is used in a wide variety of industries that require surface preparation prior to the application of a protective coating. The surface of the work piece is cleaned by a mixture of abrasive and high pressure compressed air being directed at the work piece by a blast operator. The operator holds a venturi nozzle tipped hose in his hands and controls the abrasive/air mixtyre generated at the blast machine with an "on the hose" operator switch.

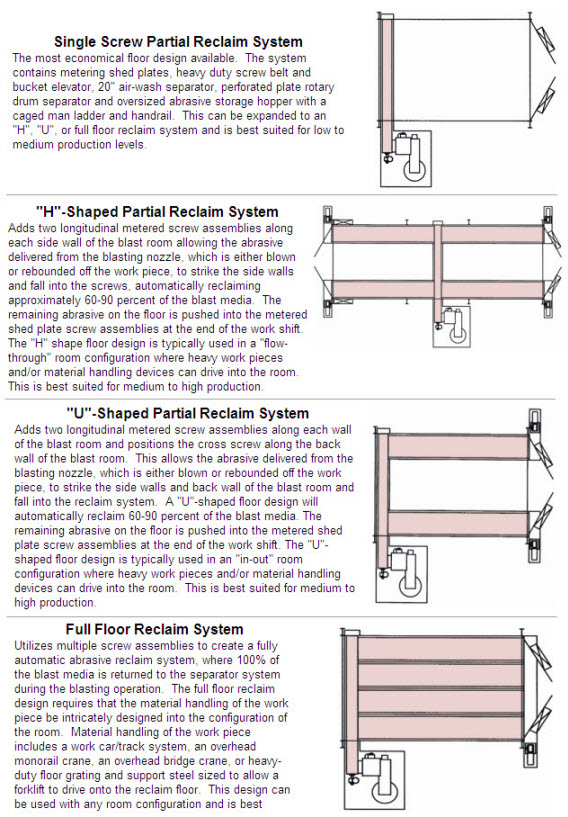

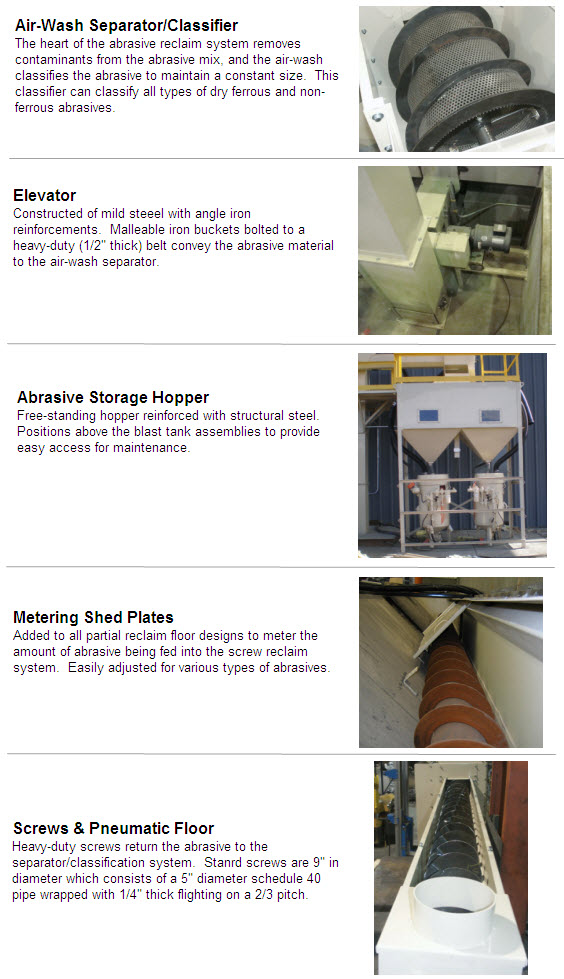

The blast room contains the abrasive being shot at the work piece as well as providing lighting and ventilation for the operator's safety. The abrasive and surface particle mix (i.e. paint chips, surface rust, mill scale, etc.) are collected by the floor reclamation system and brought back to the classifier to separate reusable abrasive from waste. The reusable abrasive is stored in a bin above the blast machine and is ready for the cycle to start again.

Industries that require this process include:

- Steel Fabricators

- Construction Equipment

- Railcars

- Steel Tanks

- Trailers

- Oil Field Equipment

- Ship Building

Environmentally Safe

|

N/A

Air-blasting eliminates many of the environmental problems and costs associated with chemical stripping because you don’t have to manage or dispose of hazardous liquids. |

Optional Features

|

N/A

Overhead Material Handling |