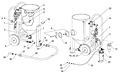

2cu’ Contractors Pressure Blast Pot

Contractors Pot

Field portable, high-production, single chamber blast machine, rated at 150 psi, (for one operator). Holds 2 cubic feet of blast media. Equipped with Millennium pneumatic remote controls and Quantum manual metering valve.

Unit of Measure

| Items |

/Asset/2cu--Contractors-Pressure-Blast-Pot.jpg /Asset/2cu--Contractors-Pressure-Blast-Pot.jpg 21490 Contractor Blast Machine List Price QUOTE

|

/Asset/2cu--Contractors-Pressure-Blast-Pot.jpg /Asset/2cu--Contractors-Pressure-Blast-Pot.jpg 02397 Ball valve, 1 1/4" with handle List Price $109.00

|

/Asset/2cu--Contractors-Pressure-Blast-Pot.jpg /Asset/2cu--Contractors-Pressure-Blast-Pot.jpg 22532 Handle, 1 1/4" ball valve List Price $22.50

|

/Asset/2cu--Contractors-Pressure-Blast-Pot.jpg /Asset/2cu--Contractors-Pressure-Blast-Pot.jpg 23674 Pusher line, 1 1/4" x 28" coupled List Price $168.00

|

/Asset/2cu--Contractors-Pressure-Blast-Pot.jpg /Asset/2cu--Contractors-Pressure-Blast-Pot.jpg 01857 Compression coupling, 1 1/4" List Price $114.00

|

|||||

| Drawing Reference No. | N/A | N/A 1 | N/A 2 | N/A 3 | N/A 4 | |||||

| Color | N/A Champagne | N/A | N/A | N/A | N/A | |||||

| Material | N/A | |||||||||

| Size | N/A | N/A 1 1/4 in | N/A 1 1/4 in | N/A 1 1/4 in | N/A 1 1/4 in | |||||

| ID | N/A | |||||||||

| Length | N/A | N/A | N/A | N/A 28 in | N/A | |||||

| Packaging | N/A Secured on skid and shrink wrapped | N/A | N/A | N/A | N/A | |||||

| Pressure | N/A 150 psi | N/A | N/A | N/A | N/A | |||||

| Part | N/A Contractor Blast Machine |

N/A

Ball valve<!--1267--> |

N/A

Handle<!--1267--> |

N/A

Pusher line<!--1267--> |

N/A

Compression coupling<!--1267--> |

|||||

| Height (Floor to Highest Point) | N/A 44 in | N/A | N/A | N/A | N/A | |||||

| Height (Floor to Highest Point)-Including Skid | N/A 49 in | N/A | N/A | N/A | N/A | |||||

| Width (Outside Hub to Hub) | N/A 28 3/4 in | N/A | N/A | N/A | N/A | |||||

| Width (Outside Hub to Hub)-Including Skid | N/A 35 in | N/A | N/A | N/A | N/A | |||||

| Length (Hose Coupling to Handle) | N/A 39 in | N/A | N/A | N/A | N/A | |||||

| Length (Hose Coupling to Handle)-Including Skid | N/A 40 in | N/A | N/A | N/A | N/A | |||||

| Machine Diameter | N/A 16 in | N/A | N/A | N/A | N/A | |||||

| Net Weight | N/A 258 lbs | N/A | N/A | N/A | N/A | |||||

| Shipping Volume | N/A 39.7 ft³ | N/A | N/A | N/A | N/A | |||||

| Shipping Weight | N/A 326 lbs | N/A | N/A | N/A | N/A | |||||

| Floor To Center of Inlet Pipe | N/A 24 3/8 in | N/A | N/A | N/A | N/A | |||||

| Floor To Center of Hose Coupling | N/A 3 1/4 in | N/A | N/A | N/A | N/A | |||||

| Outside Handles Width | N/A 19 1/4 in | N/A | N/A | N/A | N/A | |||||

| Details |

N/A

High- performance blast cleaning system removes corrosion, mill scale, and coatings from most surfaces . Produces a uniform surface texture , and creates a surface profile to increase bonding for coatings. See related literature for additional applications. Machine holds 2 cubic feet of abrasive for up to 30 minutes of continuous blasting at 100 psi with standard No. 4 nozzle (1/4-inch orifice). Requirements for Operation: The operator controls blasting from a remote control handle at the nozzle. Pressing the handle starts blasting, releasing it stops blasting. The blast machine contains abrasive and meters it into the compressed air stream. Note: |

N/A | N/A | N/A | N/A | |||||

| Advantages |

N/A

|

N/A | N/A | N/A | N/A | |||||

| Approvals and Certifications |

N/A

Blast machine pressure vessel built to American Society of Mechanical Engineers (ASME) code for 150-psi working pressure . Vessel is hydrostatically tested and National Board certified. Remote control system complies with OSHA regulation 1910.244 (b). |

N/A | N/A | N/A | N/A | |||||

|

|

||||||||||